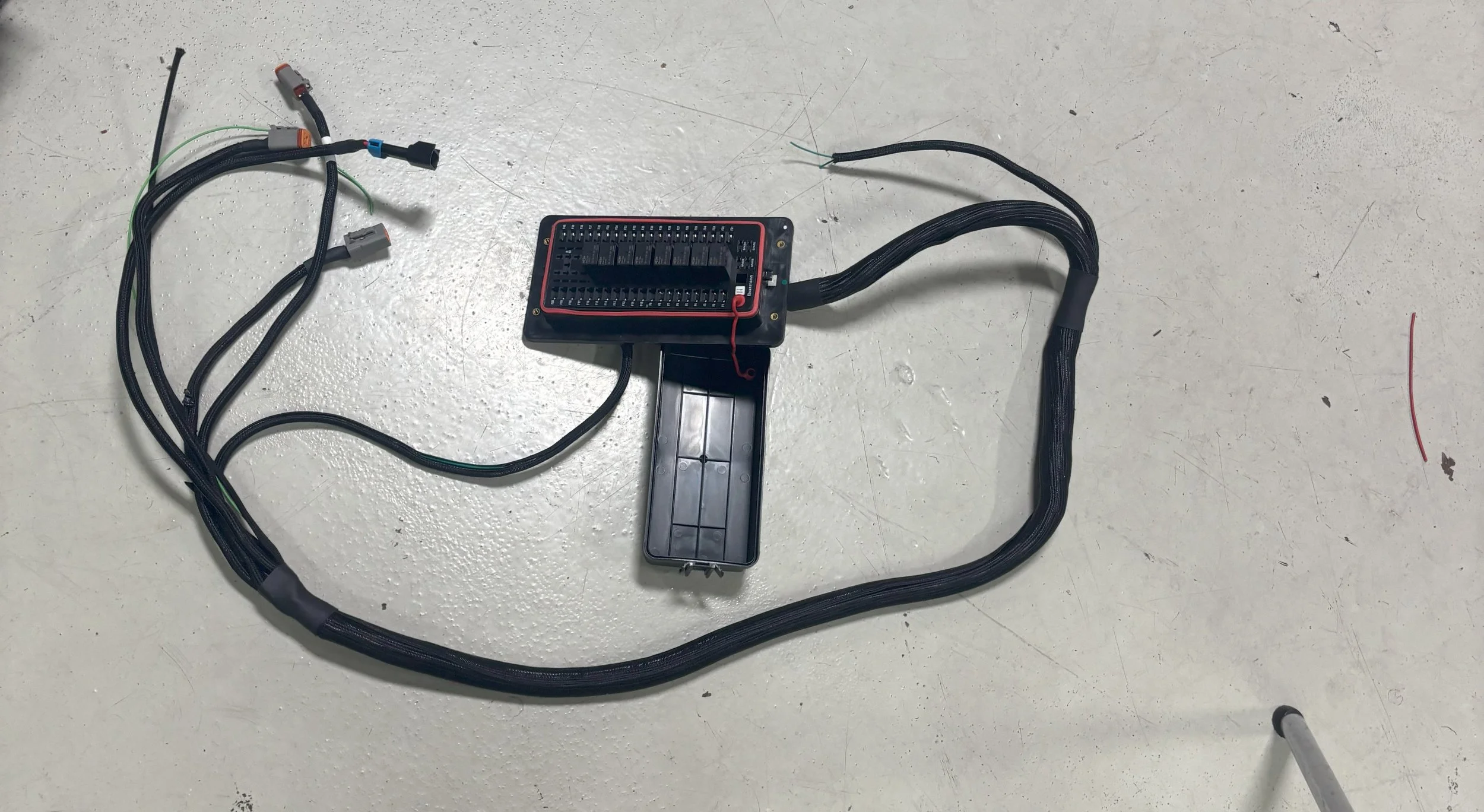

This was one of my favorite projects, Customer came to me looking to update his Fox body Mustang which was Ls Swapped . Was previously wired which was a cluster of wires and needed to be cleaned up as well as upgrade the gauge of some of the wires. Started with the fuse box, Used a Eaton Busman Fuse box, used a starter relay to provide key on power to both Fuse busbars making the whole fuse box key on, so no worry for parasitic amp draw from electrical components when the car is off. Once all was said done the vehicle pulled 1200hp and was back on the drag strip.

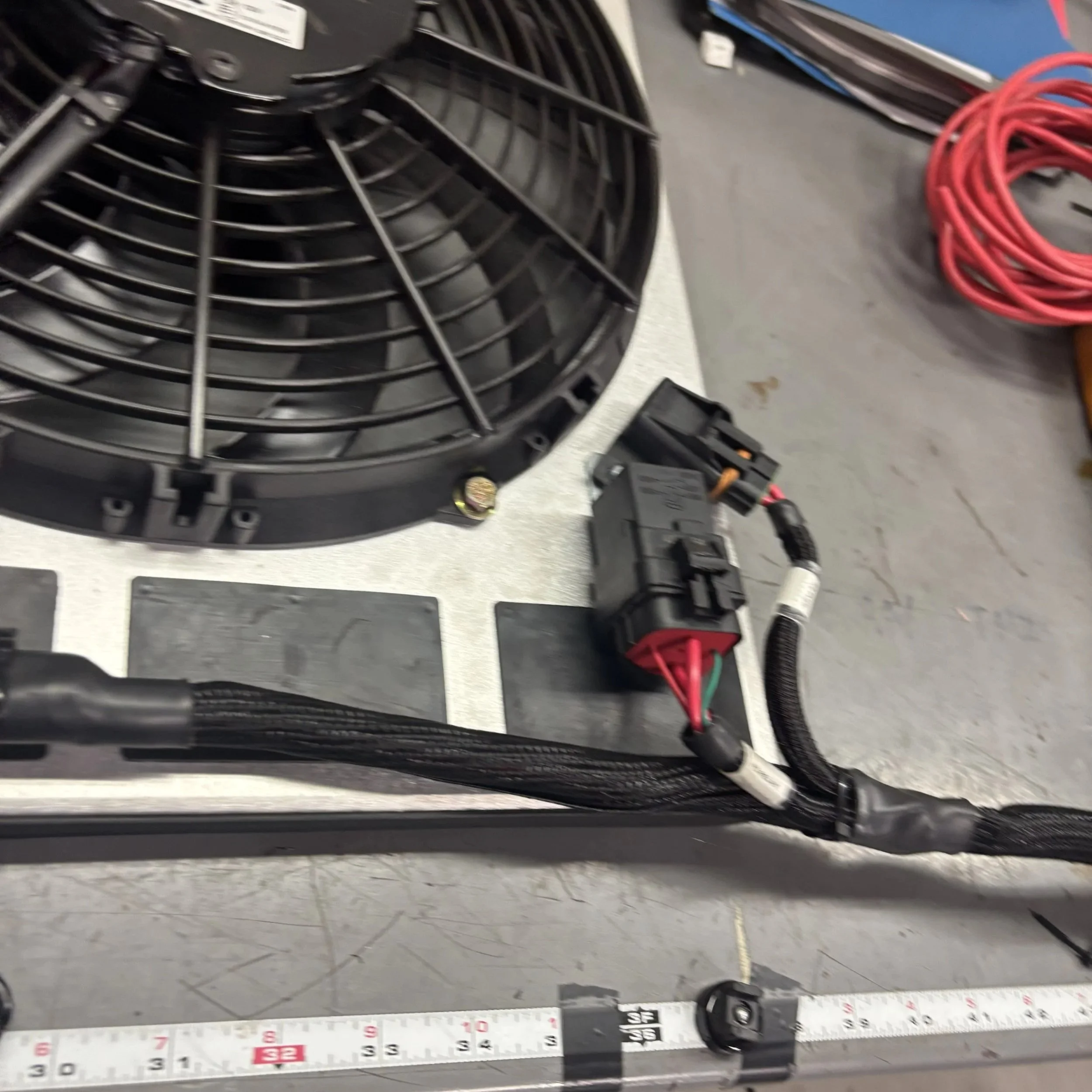

This was the first custom automotive harness I’ve designed and built. What we have here is a Spal Cooling Fan shroud Harness. Using Two Hella relays, Fused power and ground, with two trigger wires where you can set up to work with a ecu of choice